Using grinding machine for slag for construction aggregate in brazil

Transforming Industrial Byproducts into Valuable Construction Materials

Brazil’s construction industry faces increasing pressure to adopt sustainable practices while meeting growing infrastructure demands. One promising solution lies in the transformation of industrial slag into high-quality construction aggregates through advanced grinding technology. This approach not only addresses waste management challenges but also creates valuable building materials from what was previously considered industrial byproduct.

The Brazilian Context: Slag Availability and Construction Needs

Brazil generates substantial quantities of slag from its steel and metallurgical industries, particularly in industrial hubs like Minas Gerais, São Paulo, and Rio de Janeiro. Traditionally, this material has been treated as waste, occupying valuable landfill space and presenting environmental concerns. However, with proper processing through specialized grinding equipment, slag can be transformed into high-performance construction aggregates that meet stringent quality standards.

The Brazilian construction sector’s growing emphasis on sustainable building practices aligns perfectly with slag utilization. Processed slag aggregates demonstrate excellent mechanical properties, including high compressive strength, good abrasion resistance, and favorable particle shape characteristics. When properly ground and classified, these materials can replace natural aggregates in various applications, from concrete production to road base construction.

Technical Considerations for Slag Grinding Operations

Successful slag processing requires careful consideration of several technical factors. The abrasive nature of slag demands robust grinding equipment capable of handling tough materials while maintaining operational efficiency. Particle size distribution control is critical, as the final product must meet specific grading requirements for construction applications.

Moisture content presents another significant challenge. Many slag materials contain residual moisture that can affect grinding efficiency and final product quality. Modern grinding systems incorporate drying capabilities to address this issue, ensuring consistent processing regardless of initial material conditions.

Advanced Grinding Solutions for Brazilian Applications

For operations requiring ultra-fine powder production from slag materials, the MW Ultrafine Grinding Mill represents an optimal solution. This advanced system handles input sizes up to 20 mm with capacities ranging from 0.5 to 25 tph, making it suitable for various Brazilian production scenarios. The mill’s efficient pulse dust collector and muffler system ensures minimal environmental impact, a crucial consideration for operations near urban areas or sensitive ecosystems.

The MW Ultrafine Grinding Mill achieves remarkable efficiency through newly designed grinding curves of the grinding roller and ring assembly. Compared to conventional grinding systems, it delivers 40% higher production capacity with the same fineness and power consumption. The cage-type powder selector, incorporating German technology, enables precise fineness adjustment between 325-2500 meshes, with screening rates achieving d97≤5μm in a single pass.

Operational Advantages in Brazilian Conditions

The unique design features of modern grinding mills provide significant benefits for Brazilian operations. The absence of rolling bearings and screws in the grinding chamber eliminates concerns about bearing damage or loose screw-related failures. External lubrication systems enable maintenance without shutdowns, supporting continuous 24-hour operations that maximize productivity.

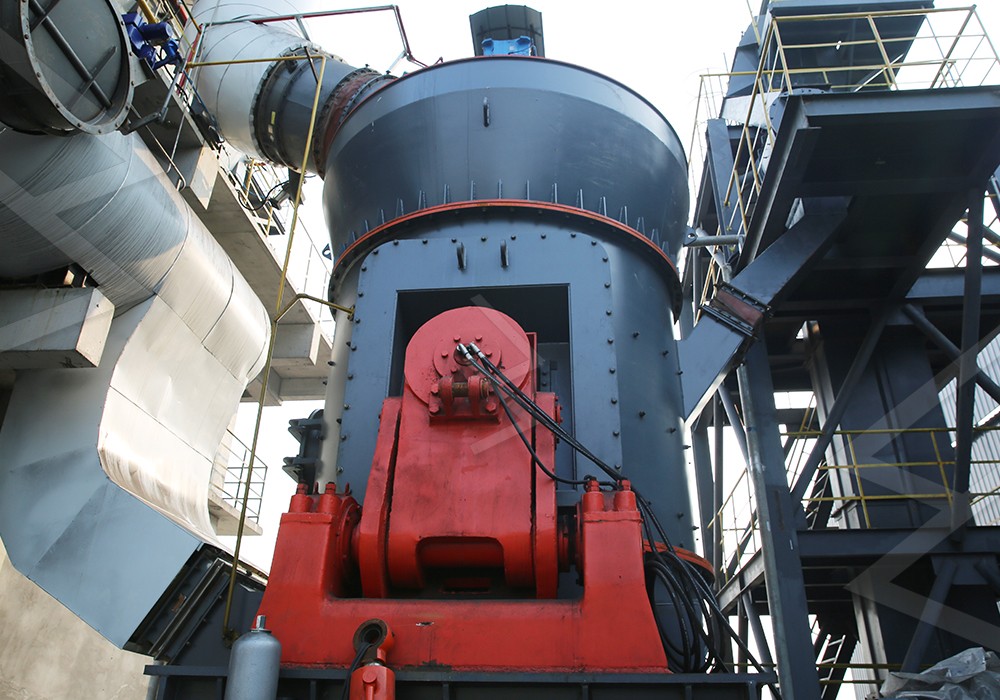

For operations processing larger quantities of slag, the LM Vertical Slag Mill offers exceptional capabilities with capacity ranging from 7-100 tph. This system integrates drying, grinding, powder selection, and conveying in a single unit, reducing footprint requirements by approximately 50% compared to ball mill systems while cutting energy consumption by 30-40%.

Environmental Compliance and Community Relations

Brazil’s environmental regulations continue to tighten, particularly in regions experiencing industrial expansion. Modern grinding equipment addresses these concerns through comprehensive dust control systems and noise reduction technologies. The MW Ultrafine Grinding Mill’s pulse dust collector ensures virtually dust-free operation, while silencers and noise elimination rooms maintain sound levels within regulatory limits.

These environmental features not only ensure compliance with Brazilian standards but also support positive community relations—an increasingly important consideration for industrial operations near residential areas. The transformation of waste materials into valuable construction products further enhances the sustainability profile of operations utilizing slag grinding technology.

Economic Viability and Market Opportunities

The economic case for slag grinding in Brazil continues to strengthen as natural aggregate sources face depletion and transportation costs rise. Processed slag aggregates command premium prices in specific applications where their technical properties provide advantages over conventional materials. The lower energy consumption of advanced grinding systems, combined with reduced waste disposal costs, creates compelling financial returns for forward-thinking operators.

Brazil’s ongoing infrastructure development programs, including transportation networks, energy projects, and urban development initiatives, provide substantial market opportunities for high-quality construction aggregates. Slag-based materials offer technical advantages in many of these applications while supporting sustainability objectives that are increasingly incorporated into public procurement criteria.

Implementation Considerations for Brazilian Operations

Successful implementation of slag grinding operations requires careful planning around several key factors. Site selection should consider proximity to both slag sources and potential markets to minimize transportation costs. Power availability and cost represent significant operational considerations, making energy-efficient grinding systems particularly valuable in the Brazilian context.

Local technical support and spare parts availability ensure minimal downtime—a critical factor in maintaining profitability. Equipment suppliers with established Brazilian presence and support networks provide significant advantages in this regard, offering prompt technical service and genuine spare parts to maintain operational continuity.

Future Outlook and Technological Evolution

The future of slag utilization in Brazilian construction looks promising, with technological advancements continuing to improve processing efficiency and product quality. Digitalization trends are reaching grinding operations, with advanced control systems optimizing performance parameters in real-time based on material characteristics and production requirements.

Research continues into new applications for processed slag, potentially expanding markets beyond traditional construction aggregates. These developments, combined with Brazil’s commitment to sustainable development, position slag grinding as a growth sector within the country’s industrial landscape.

Frequently Asked Questions

What are the primary types of slag suitable for aggregate production in Brazil?

Blast furnace slag and steel slag from Brazil’s metallurgical industry represent the most common materials processed into construction aggregates. These materials demonstrate excellent cementitious properties when properly ground and can replace natural aggregates in many applications.

How does processed slag aggregate compare to natural aggregates in terms of performance?

Processed slag aggregates often demonstrate superior mechanical properties, including higher compressive strength and better abrasion resistance. Their angular particle shape provides excellent interlock characteristics in concrete and asphalt applications.

What environmental benefits does slag utilization provide?

Slag utilization reduces landfill requirements, conserves natural aggregate resources, and typically has a lower carbon footprint than quarrying and processing virgin materials. The grinding process itself can be designed to minimize dust emissions and noise pollution.

What maintenance requirements should Brazilian operators anticipate?

Modern grinding mills require regular inspection of wear parts, with typical maintenance intervals depending on material abrasiveness. Systems with external lubrication and accessible components significantly reduce maintenance time and complexity.

How does the MW Ultrafine Grinding Mill handle variations in slag composition?

The mill’s adjustable grinding parameters and precision classification system accommodate normal variations in slag composition. The cage-type powder selector can be configured to maintain consistent product quality despite feed material fluctuations.

What power requirements are typical for slag grinding operations?

Power consumption varies with material hardness and required fineness, but modern systems like the MW Ultrafine Grinding Mill achieve significant energy savings—typically 30-50% less than conventional grinding systems for equivalent output.

Can grinding systems process slag with high moisture content?

Integrated drying systems in mills like the LM Vertical Slag Mill can handle materials with significant moisture content. For extremely wet materials, pre-drying may be recommended to optimize grinding efficiency.

What particle size ranges can be achieved with modern grinding equipment?

Advanced systems can produce materials ranging from coarse aggregates to ultra-fine powders. The MW Ultrafine Grinding Mill, for example, produces powders between 325-2500 meshes, while other systems can maintain specific particle size distributions for aggregate applications.