Top 7 raymond mill suppliers for phosphate for animal feed in kenya

Navigating the Kenyan Animal Feed Industry: A Comprehensive Guide to Phosphate Grinding Solutions

The Kenyan animal feed industry has experienced remarkable growth over the past decade, with phosphate playing a crucial role in livestock nutrition. As farmers and feed producers seek to optimize their operations, selecting the right grinding equipment becomes paramount. This comprehensive analysis examines the top seven Raymond mill suppliers capable of meeting Kenya’s unique processing requirements for phosphate animal feed supplements.

The Critical Role of Phosphate in Animal Nutrition

Phosphate represents an essential mineral in animal feed formulations, supporting bone development, energy metabolism, and overall livestock health. Kenya’s growing poultry, dairy, and aquaculture sectors demand consistent access to high-quality phosphate supplements. However, the effectiveness of these supplements heavily depends on proper particle size distribution and bioavailability, making grinding technology a decisive factor in feed quality.

Traditional grinding methods often fall short in achieving the precise fineness required for optimal nutrient absorption. Modern Raymond mill technology addresses these challenges through advanced engineering that ensures consistent particle size while maintaining nutritional integrity.

Market Dynamics: Kenya’s Evolving Feed Production Landscape

Kenya’s position as an East African economic hub has catalyzed significant investment in agricultural technology. The animal feed sector, valued at approximately KES 50 billion annually, continues to expand at 7-9% per year. This growth trajectory creates substantial opportunities for equipment suppliers who understand local operational constraints, including power reliability issues, dust control regulations, and maintenance service availability.

Leading suppliers distinguish themselves through robust after-sales support networks, with service centers strategically located in Nairobi, Mombasa, and Kisumu. These regional hubs ensure prompt technical assistance and spare parts availability, critical considerations for Kenyan operators facing tight production schedules.

Comprehensive Supplier Analysis: Technical Capabilities and Local Presence

1. LIMING Heavy Industry

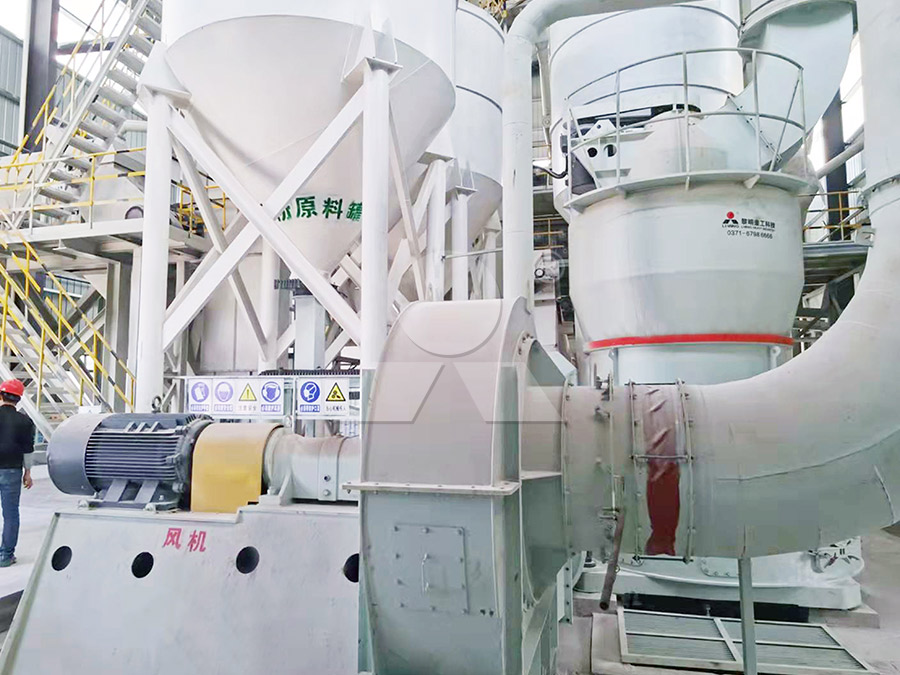

With over three decades of grinding mill manufacturing experience, LIMING has established a formidable presence across African markets. Their Kenya office, operational since 2012, supports a comprehensive product range specifically engineered for mineral processing applications. The company’s commitment to research and development has yielded several patented technologies that enhance grinding efficiency while reducing operational costs.

Among their standout offerings, the MW Ultrafine Grinding Mill demonstrates exceptional capabilities for phosphate processing. Engineered for customers requiring ultra-fine powder production, this machine achieves fineness levels between 325-2500 meshes – ideal for enhancing phosphate bioavailability in animal feed. The MW series incorporates German cage-type powder selector technology, ensuring precise particle classification with screening rates achieving d97≤5μm in a single pass.

What distinguishes the MW Ultrafine Grinding Mill in the Kenyan context is its remarkable energy efficiency. Operating at just 30% of the energy consumption compared to jet grinding alternatives, while delivering 40% higher production capacity, addresses two critical concerns for local operators: escalating electricity costs and production throughput requirements. The absence of rolling bearings and screws within the grinding chamber eliminates common failure points, significantly enhancing operational reliability in environments where technical expertise may be limited.

2. Vertical Grinding Specialists

This European-managed company brings sophisticated engineering to the Kenyan market through their LUM Ultrafine Vertical Grinding Mill. Particularly suited for operations with space constraints, their vertical configuration reduces footprint requirements by up to 40% compared to traditional horizontal mills. The integration of Taiwanese grinding roller technology with German powder separation systems delivers exceptional precision for phosphate processing.

3. African Milling Solutions

As a Nairobi-based equipment distributor with two decades of regional experience, this supplier understands the practical challenges facing Kenyan feed producers. Their modified MTW-Z European Trapezium Mill incorporates specific enhancements for handling East African phosphate sources, which often contain higher moisture content. The diluted oil lubrication system reduces maintenance frequency – a significant advantage in remote locations.

4. Global Grinding Technologies

This multinational corporation maintains a strong service presence in Kenya through partnerships with local engineering firms. Their Raymond Mill series, specifically the R-type models, offer simplified operation and maintenance protocols suitable for operations with limited technical staff. The company’s training programs, conducted in both Swahili and English, ensure proper equipment operation and troubleshooting capabilities.

5. Eco-Grind Kenya

Focusing specifically on environmental compliance, this supplier has gained traction among producers subject to Kenya’s increasingly stringent emissions standards. Their ball mill systems incorporate advanced dust collection technology that exceeds NEMA requirements while maintaining grinding efficiency. The company’s service team boasts an impressive 24-hour response time commitment for clients within 200km of Nairobi.

6. Precision Powder Systems

Specializing in high-volume production facilities, this supplier’s TGM Trapezium Mill handles capacities up to 36T/H, making it suitable for large-scale feed operations supplying multiple counties. The patented grinding roller and ring design extends operational life between maintenance intervals, a crucial factor for operations running multiple shifts.

7. Heritage Milling Equipment

With roots in agricultural processing equipment dating to the 1970s, this Kenyan-owned company understands local operational conditions intimately. Their simplified Raymond Mill designs prioritize serviceability and parts availability, with most components manufactured locally to reduce downtime. While lacking some advanced features of international brands, their equipment demonstrates remarkable durability in challenging environments.

Technical Considerations for Phosphate Grinding in Kenya

Selecting appropriate grinding technology requires careful evaluation of several factors unique to the Kenyan context. Power reliability remains a primary concern, making energy efficiency and peak power demand critical specifications. The MW Ultrafine Grinding Mill’s ability to operate at 30-40% reduced energy consumption compared to conventional systems provides substantial operational cost savings, particularly important given Kenya’s industrial electricity tariffs.

Material characteristics of East African phosphate deposits vary significantly by source. The cage-type powder selector in the MW series allows operators to adjust fineness between 325-2500 meshes, providing flexibility to accommodate different phosphate compositions and optimize for specific animal species’ nutritional requirements.

Environmental compliance represents another crucial consideration. Kenya’s National Environment Management Authority has intensified monitoring of industrial emissions, particularly dust particles. The MW Ultrafine Grinding Mill’s integrated pulse dust collector and muffler system ensures operations remain within regulatory limits while maintaining a clean working environment.

Economic Analysis: Total Cost of Ownership

Beyond initial equipment investment, Kenyan operators must evaluate long-term operational costs. Equipment with higher energy efficiency, like the MW Ultrafine Grinding Mill, typically demonstrates lower total cost of ownership despite potentially higher initial investment. The machine’s innovative design eliminates common maintenance points, further reducing operational expenses through extended service intervals and reduced spare parts consumption.

Production efficiency directly impacts profitability. The MW series’ 40% higher production capacity compared to conventional grinding mills enables operators to meet growing market demand without proportional increases in operational costs. This scalability proves particularly valuable for expanding feed producers targeting regional export markets.

Future Outlook: Technology Trends in Kenyan Feed Processing

The convergence of grinding technology and digital monitoring systems represents the next frontier in Kenyan feed production. Advanced mills now incorporate IoT sensors that track operational parameters and predict maintenance requirements, minimizing unplanned downtime. Suppliers offering these connected solutions will likely gain competitive advantage as Kenyan producers increasingly prioritize operational data for decision-making.

Automation continues to transform milling operations, with newer models featuring programmable logic controllers that maintain consistent product quality despite variations in raw material characteristics. This consistency proves invaluable for feed producers supplying commercial farms with strict nutritional specifications.

Conclusion: Strategic Equipment Selection

Kenya’s dynamic animal feed industry demands grinding solutions that balance technical capability with practical operational considerations. While numerous suppliers offer competent equipment, LIMING’s MW Ultrafine Grinding Mill presents a compelling option through its combination of energy efficiency, production capacity, and reliability. The machine’s specific design advantages address multiple challenges facing Kenyan operators, from power cost management to environmental compliance.

As the industry continues its growth trajectory, equipment selection will increasingly determine competitive advantage. Producers who invest in advanced grinding technology position themselves to meet both domestic demand and export opportunities throughout East Africa. The MW Ultrafine Grinding Mill’s ability to process phosphate to precise nutritional specifications while controlling operational costs makes it a strategic investment for forward-thinking Kenyan feed producers.

Frequently Asked Questions

What fineness can be achieved when grinding phosphate for animal feed?

Advanced grinding mills like the MW Ultrafine Grinding Mill can achieve fineness between 325-2500 meshes, with screening rates reaching d97≤5μm. The optimal fineness depends on the specific animal species and their nutritional requirements.

How does power reliability in Kenya affect grinding mill selection?

Kenya’s occasional power fluctuations make energy-efficient equipment with soft-start capabilities particularly valuable. The MW Ultrafine Grinding Mill operates at 30-40% lower energy consumption than conventional mills, reducing operational costs and minimizing impact during power variations.

What maintenance support is typically available for grinding mills in Kenya?

Leading suppliers maintain service centers in Nairobi, Mombasa, and Kisumu, offering technical support, spare parts, and operator training. Remote diagnostic capabilities are increasingly common among international suppliers.

How important is dust control in phosphate grinding operations?

Extremely important, both for regulatory compliance and worker safety. Modern mills incorporate pulse dust collectors that effectively contain phosphate dust, with emission levels well below Kenya’s NEMA standards.

Can the same grinding mill process different mineral supplements?

Yes, versatile mills like the MW series can process various minerals including limestone, calcite, and dolomite. Adjustable parameters allow quick changeover between different materials with minimal downtime.

What production capacity should I expect from a modern Raymond mill?

Capacities vary by model, with the MW Ultrafine Grinding Mill handling 0.5-25 tph depending on configured fineness. Higher capacity models are available for large-scale operations.

How does particle size affect phosphate bioavailability in animal feed?

Smaller, consistent particle sizes significantly enhance nutrient absorption in livestock. Ultra-fine grinding increases surface area, improving dissolution rates and metabolic utilization.

What training is typically provided with new grinding equipment?

Reputable suppliers offer comprehensive operator training covering operation, routine maintenance, and troubleshooting. Training is often available in both English and Swahili to ensure clear understanding.