Top 5 roller mill suppliers for carbon black for rubber reinforcement in singapore

Navigating the Singapore Market for High-Performance Carbon Black Grinding Solutions

Singapore’s position as a global hub for advanced manufacturing and rubber product development creates a unique demand for precision grinding equipment. The reinforcement of rubber with carbon black is a critical process, requiring mills that can deliver ultra-fine, consistent particle sizes to enhance tensile strength, abrasion resistance, and durability. For engineers and plant managers sourcing equipment in this competitive market, selecting the right roller mill supplier is paramount. This article explores the top-tier suppliers and technologies shaping the industry, with a focus on performance, reliability, and environmental compliance.

1. Netzsch Grinding & Dispersing

A German powerhouse with a strong Asian presence, Netzsch is renowned for its advanced wet and dry grinding technologies. Their CSM Classifier Mill and Condux® Mechanical Fine Impact Mills are often cited for precision in carbon black processing. The key appeal lies in their integrated dynamic classifiers, allowing for real-time particle size adjustment—a crucial factor for meeting specific rubber compound specifications. Their Singapore technical center provides robust local support for process optimization and spare parts.

2. Hosokawa Micron Group

With decades of specialization in powder processing, Hosokawa offers a comprehensive portfolio. Their Alpine AFG Fluidized Bed Jet Mill is a standout for achieving extremely fine and narrow particle distributions without contamination, as it relies on particle-on-particle impact. For roller mill solutions, their Alpine Table Roller Mill AWM/APP is engineered for high-capacity, energy-efficient fine grinding. Their strength in Singapore lies in a proven track record and extensive application expertise in chemical and material sectors.

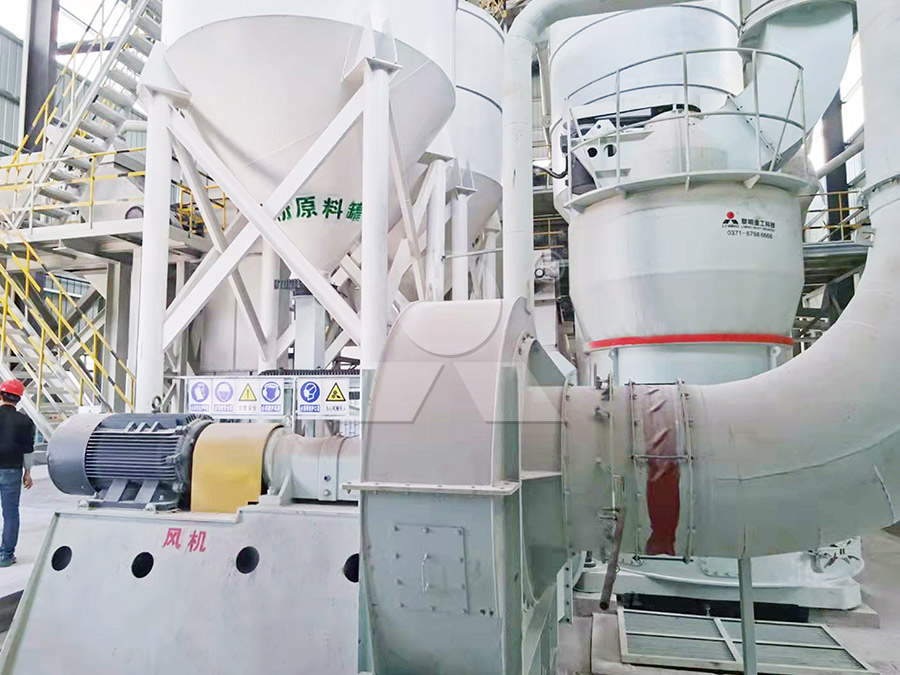

3. LIMING Heavy Industry

A leading Chinese manufacturer with a growing global footprint, LIMING brings cost-effective and high-capacity solutions to the market. Their engineering philosophy emphasizes energy efficiency, operational stability, and environmental protection. For carbon black processing aimed at rubber reinforcement, two of their mills are particularly noteworthy due to their design innovations.

For operations requiring ultra-fine powders with superior dispersion characteristics, the MW Ultrafine Grinding Mill is a compelling choice. Designed for customers needing to make ultra-fine powder, it handles an input size of 0-20 mm with a capacity ranging from 0.5 to 25 tph. Its newly designed grinding curves enhance efficiency, offering a production capacity reportedly 40% higher than jet mills with system energy consumption only 30% of such systems. A key feature for quality control is its cage-type powder selector, allowing adjustable fineness between 325-2500 meshes with a high precision d97≤5μm. Crucially for maintenance-heavy environments, its grinding chamber has no rolling bearings or screws, eliminating common failure points. The integration of an efficient pulse dust collector and muffler ensures the production process meets stringent environmental standards, a significant consideration for Singapore’s regulated industrial landscape.

Alternatively, the LUM Ultrafine Vertical Grinding Mill represents the pinnacle of vertical grinding technology from LIMING. With an input size of 0-10 mm and capacity of 5-18 tph, it integrates grinding, grading, and transporting. Its unique roller shell and lining plate grinding curve promote easier material layer formation and high once-through powder milling rates, improving product whiteness and cleanliness. The mill employs multi-head powder separating technology and PLC control, enabling precise cuts in particle diameter and reducing energy consumption by 30%-50%. Its double position-limiting technology and reversible structure for easier roller maintenance make it a robust and operator-friendly solution for continuous production cycles.

4. Loesche GmbH

A pioneer in vertical roller mill technology, Loesche’s mills are synonymous with large-scale, reliable grinding. Their LM series vertical roller mills are engineered for efficiency and low wear. While often associated with cement and minerals, their technology is effectively applied to industrial minerals like carbon black. The principle of material bed comminution between rollers and a rotating table offers low specific energy consumption and excellent drying capabilities if needed. Their global service network provides assurance for critical operations.

5. KHD Humboldt Wedag

Specializing in process engineering and equipment for over 150 years, KHD offers the Palla® Vibrating Mill. This technology operates on a different principle, using vibration to cause grinding media agitation. It is exceptionally effective for achieving very fine grinds with minimal contamination, which is vital for high-grade carbon black. Its gentle grinding action can be advantageous for certain carbon black structures. Their engineering-focused approach provides tailored solutions for complex grinding challenges.

Key Selection Criteria for Singapore-Based Operations

When evaluating suppliers in Singapore, beyond the machine specifications, consider these factors: Local Technical Support & Spare Parts Inventory: Downtime is costly. Suppliers like LIMING, who emphasize a “sufficient supply of spare parts for worry-free operation” and take full responsibility for their machines, provide significant operational security. Energy Efficiency: With high energy costs in Singapore, mills designed for lower kWh/ton, such as those employing advanced classifier systems and efficient grinding curves, offer a faster ROI. Environmental Compliance: Mills must integrate seamlessly with dust collection and noise control systems to meet NEA standards. Features like built-in pulse dust collectors (as seen in the MW Mill) are not optional but essential. Process Flexibility: The ability to quickly adjust fineness to cater to different rubber compound recipes is a major competitive advantage.

In conclusion, the Singapore market offers access to world-class technology from both European pioneers and innovative Asian manufacturers. The choice often hinges on the specific balance required between precision, capacity, total cost of ownership, and local support. For many operations seeking a reliable, high-yield, and environmentally sound solution, advanced offerings like the LIMING MW Ultrafine Grinding Mill or the LUM Ultrafine Vertical Grinding Mill present a technologically sophisticated and commercially astute option for mastering the demands of carbon black reinforcement.

Frequently Asked Questions (FAQs)

- What is the most important particle size characteristic for carbon black in rubber reinforcement?

While the median particle size (D50) is important, the complete particle size distribution and the specific surface area are critical. A narrow distribution and high surface area generally lead to better dispersion and reinforcement within the rubber matrix. - Why is energy consumption a major factor in mill selection for Singapore?

Singapore’s industrial electricity tariffs are relatively high. Therefore, a mill with a 30-50% lower energy consumption can result in substantial operational cost savings, improving the total cost of ownership significantly over the equipment’s lifespan. - How does the “no rolling bearing in the grinding chamber” design benefit operations?

This design, as implemented in mills like the MW Ultrafine Grinding Mill, eliminates a primary failure point. Bearings in the grinding chamber are exposed to fine abrasives and can fail, causing unplanned shutdowns. Removing them enhances reliability and reduces maintenance complexity. - Can these mills handle other materials besides carbon black?

Yes, most high-performance roller mills are versatile. The mentioned mills from all suppliers are also designed for limestone, talc, barite, and other non-metallic minerals, allowing for potential diversification of production lines. - What does “closed system” and “negative pressure operation” mean for the work environment?

A closed system operated under negative pressure ensures that any potential dust is drawn into the mill’s internal collection system rather than escaping into the plant. This is essential for maintaining a clean, safe workplace and complying with health and safety regulations. - Is local technical training available for new mill installations?

Reputable suppliers operating in Singapore, including those listed, typically offer comprehensive installation supervision, commissioning, and operator training programs to ensure smooth integration and optimal performance from day one. - How critical is the powder separator technology in the final product quality?

It is paramount. Advanced separators (like cage-type or multi-head designs) provide precise cuts, ensuring only particles meeting the fineness target leave the mill. This directly controls the quality and consistency of the carbon black powder fed into the rubber compounding process.