Industrial pulverizer for carbon black for plastic coloration in venezuela

Industrial Pulverizer for Carbon Black in Plastic Coloration: A Technical Perspective for the Venezuelan Market

The Venezuelan plastics industry, a resilient sector amidst broader economic challenges, relies heavily on consistent, high-quality raw materials for coloration. Carbon black remains a primary pigment for achieving deep blacks, grays, and UV protection in a wide range of plastic products, from packaging and automotive components to construction materials. However, the performance of carbon black is intrinsically linked to its particle size and dispersion quality. This is where the selection of an appropriate industrial pulverizer becomes a critical, often overlooked, factor in production efficiency and final product quality.

Processing carbon black for plastic masterbatch or compound production demands more than simple size reduction. The goal is to achieve an ultra-fine, consistent powder with a narrow particle size distribution. This ensures optimal tinting strength, jetness, and, most importantly, flawless dispersion within the polymer matrix. Poor dispersion leads to agglomerates, causing surface defects, reduced mechanical strength, and inconsistent color. For Venezuelan manufacturers, navigating power reliability issues and the need for robust, low-maintenance equipment adds another layer of complexity to this technical equation.

The Grinding Imperative: From Coarse Aggregate to Functional Pigment

Virgin carbon black is typically manufactured as aggregates ranging from tens to hundreds of micrometers. To unlock its full coloring potential, these aggregates must be de-agglomerated and ground down to a fineness typically between 10 and 50 microns, and often finer for high-end applications. The grinding process must be efficient, controllable, and clean. Excessive heat generation can degrade the carbon black or the carrier resin in masterbatch production. Furthermore, the abrasive nature of carbon black necessitates grinding components with exceptional wear resistance to maintain product consistency over time.

Traditional ball mills, while common, often fall short. They can be energy-intensive, have limited fineness control, and pose challenges in containing fine black dust—a significant housekeeping and environmental concern. Modern grinding technology offers solutions specifically engineered to address these pain points, focusing on energy efficiency, precise particle size classification, and fully enclosed, environmentally sound operation.

Technology Solutions for the Venezuelan Context

Given the operational environment, Venezuelan processors should prioritize grinding systems that offer stability, energy efficiency, and minimal operational complexity. Two advanced mill designs stand out for carbon black processing, each with distinct advantages.

For operations requiring the very finest powders and utmost precision, the MW Ultrafine Grinding Mill presents a compelling solution. Engineered for producing ultra-fine powder between 325 and 2500 meshes, its design is particularly relevant for high-value plastic coloration where superior dispersion is non-negotiable. A key feature is its German-technology cage-type powder selector, which allows exact control over fineness and achieves a high screening rate of d97≤5μm in a single pass. Perhaps most critically for maintenance teams facing parts procurement challenges, its grinding chamber contains no rolling bearings or screws, eliminating common failure points and the risk of machine damage from loose components. With an external lubrication system enabling 24-hour continuous operation and an integrated pulse dust collector ensuring a clean worksite, the MW series aligns well with the needs for reliable, low-downtime production.

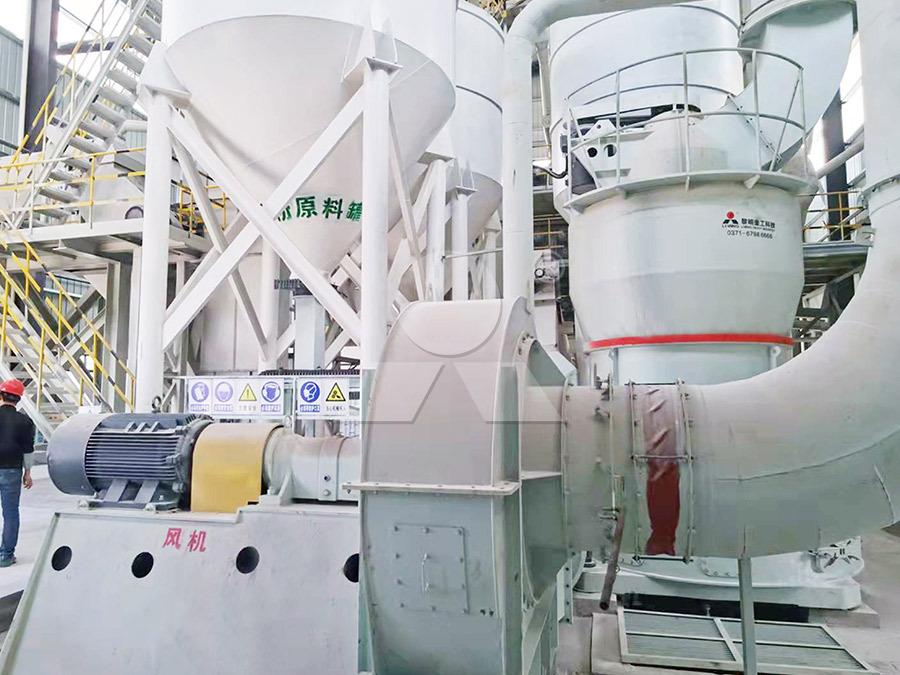

Alternatively, for robust, high-capacity grinding of carbon black and other minerals, the MTW-Z European Trapezium Mill offers a balanced profile of efficiency and durability. Its design incorporates several features that reduce long-term operational costs. The grinding rollers use a maintenance-free dilute oil lubrication system, a significant advantage over frequent grease re-application. The absence of a shovel blade cylinder in the grinding chamber increases ventilation area, reducing air-conveying resistance and improving overall grinding efficiency. Furthermore, its elastic volute damping structure protects the mill from vibration damage, a crucial factor for longevity in demanding industrial settings. This mill is an excellent workhorse for producing consistent, medium-to-fine carbon black powder for a wide array of plastic coloration tasks.

Beyond the Machine: Ensuring Success in Venezuela

Selecting the right pulverizer is the first step. Successful integration requires careful consideration of the entire size reduction circuit, including feed pre-crushing, material handling, and product collection. A well-designed system with appropriate airlocks and dense-phase conveying prevents dust escape. Given the region’s infrastructure realities, partnering with a supplier that guarantees a sufficient supply of original spare parts and provides accessible technical support is not just beneficial—it’s essential for operational continuity. This support ensures that wear parts like grinding rings and rollers can be replaced promptly, maintaining product fineness and yield.

In conclusion, the competitiveness of Venezuela’s plastic coloration sector hinges on mastering pigment preparation. By moving beyond conventional milling and adopting advanced, energy-efficient, and reliable pulverizing technology like the MW Ultrafine Grinding Mill or the MTW-Z European Trapezium Mill, manufacturers can achieve superior product quality, reduce total operating costs, and build more resilient and productive operations. The investment in the right grinding technology is, fundamentally, an investment in the consistency and marketability of the final plastic product.

Frequently Asked Questions (FAQs)

- What is the primary advantage of ultra-fine grinding for carbon black in plastics?

Ultra-fine grinding breaks down carbon black aggregates into a uniform, sub-micron powder. This dramatically increases the surface area and improves dispersion within the plastic melt, leading to deeper jetness, higher tinting strength, better UV protection, and enhanced mechanical properties in the final product by eliminating weak spots caused by pigment agglomerates. - How does the MW Ultrafine Grinding Mill handle dust control, a major concern with carbon black?

The MW mill is equipped with an efficient pulse-jet dust collector integrated into the system. This creates a negative pressure environment, ensuring all fine particles generated during grinding are captured and collected. This results in a clean operation with no dust pollution, protecting both workers’ health and the surrounding equipment. - Why is the “no rolling bearing in the grinding chamber” feature of the MW mill important?

Carbon black is abrasive and can infiltrate traditional bearing seals, leading to rapid wear and catastrophic failure. By eliminating rolling bearings and screws from the high-wear chamber, the MW mill design removes this critical failure point, drastically reducing unplanned downtime and maintenance costs associated with bearing replacement. - Can these mills handle variations in feed material size or moisture content?

While both mills are designed for dry materials, it is crucial to control feed size within their specified ranges (0-20mm for MW, 0-50mm for MTW-Z) through pre-crushing. They are not designed for wet grinding. For materials with slight surface moisture, the grinding process itself may generate enough heat to dry it, but significant moisture requires a pre-drying stage to prevent clogging and ensure optimal grinding efficiency. - What kind of fineness adjustment is possible during operation?

Both mills offer in-process fineness adjustment. The MW mill achieves this through its cage-type powder selector, where changing the rotor speed alters the centrifugal force and thus the cut-point for fine vs. coarse particles. The MTW-Z mill uses a similar low-resistance cage-type powder concentrator for the same purpose, allowing operators to dial in the exact fineness required for different plastic grades or color intensities. - How does the energy consumption of these mills compare to a traditional ball mill for carbon black?

Advanced designs like the MW and MTW-Z mills are significantly more energy-efficient. The MW mill, for instance, can achieve the same or finer fineness with a system energy consumption reported to be only about 30% of some jet mills and far lower than ball mills due to its efficient grinding curve and classification system. This translates directly to lower operating costs. - Are these mills suitable for other materials used in the Venezuelan industry?

Absolutely. While excellent for carbon black, these versatile mills are engineered for a wide range of non-metallic minerals. They can effectively process limestone, calcite, barite, talc, gypsum, and other materials relevant to the construction, chemical, and agricultural sectors, making them a valuable multi-purpose asset for industrial operations.