Roller mill for cement clinker for cement production in iran

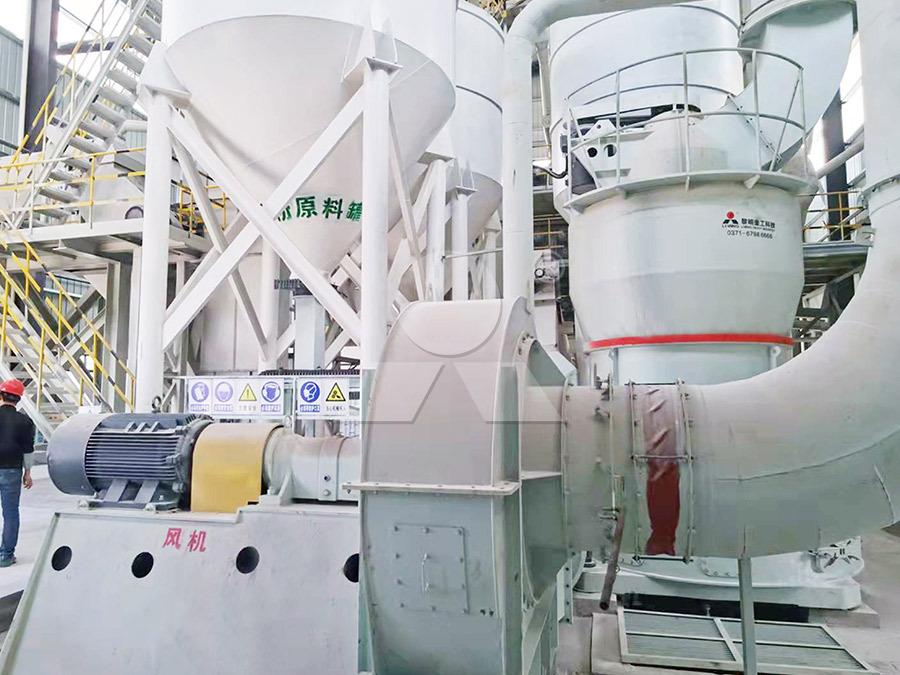

Roller Mill for Cement Clinker: Optimizing Cement Production in Iran The Iranian cement industry stands as a pillar of national infrastructure and economic development. With ambitious construction projects and a focus on export markets, the demand for high-quality, efficiently produced cement is stronger than ever. At the heart of modern cement manufacturing lies the critical process of clinker grinding. Moving beyond traditional ball mills, advanced roller mill technology has become the benchmark for producers seeking to enhance productivity, reduce operational costs, and meet stringent environmental standards. Roller mills, utilizing the principle of material bed comminution between grinding rollers and a…

Read more